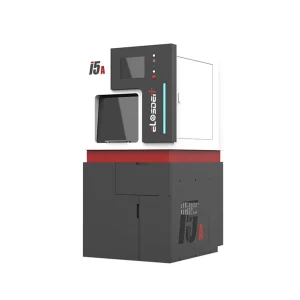

Techno-Gaz Milling Machine

Overview : Tecno-Gaz Vector

The Tecno-Gaz Vector is a cutting-edge intermediate milling machine designed for dental laboratories seeking to maximize their return on investment by leveraging CAD-CAM technology. This desktop milling machine is engineered to provide unparalleled ease of use, making it an ideal solution for dental professionals who want to streamline their workflow and achieve exceptional results.

With its advanced numerical control system featuring 5 axes continuously interpolated, the Tecno-Gaz Vector offers unparalleled precision and accuracy, allowing dental technicians to create complex restorations with ease. Its compact design and user-friendly interface make it simple to operate, even for those with limited experience.

The Tecno-Gaz Vector is designed to meet the demands of modern dental laboratories, providing a high level of flexibility and versatility. Its advanced technology and precision engineering enable dental technicians to create a wide range of restorations, from simple crowns and bridges to complex implant-supported restorations.

Whether you’re a dental laboratory looking to upgrade your milling capabilities or a dental technician seeking to expand your services, the Tecno-Gaz Vector is an excellent choice. Its advanced technology, ease of use, and durability make it an essential tool for any dental laboratory seeking to stay ahead of the curve in the rapidly evolving world of CAD-CAM dentistry.

Linear movements on 3 Cartesian axes

with rectified ball-recirculation screws

driven by brushless motors with absolute

encoders for continuous position control

while the 2 rotary axes use the same

motors with epicyclic gearboxes.

Thanks to the ±30° inclination

of the axes, Vector is able

to complete highly complex

machining operations with

high undercuts

Allows you to view in real

time the operations inside

the milling chamber.

Thanks to the 3.2 KW electrospindle of Tecno-Gaz Vector, it is possible to process any kind

of “hard” material on any type of machining. It is

possible to autonomously mill threaded prostheses,

abutments, bars, etc… with excellent quality and

timing

18 Automatic exchange tools with

measurement and verification technology

using a very high precision sensor.